Development of Coated PLA Films Containing a Commercial Olive Leaf Extract for the Food Packaging Sector

Abstract

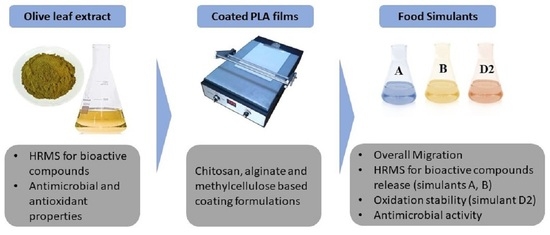

:1. Introduction

2. Materials and Methods

2.1. Bioactivity of Olive Leaf Extract

2.1.1. Total Phenolic Content

2.1.2. In Vitro Antioxidant Capacity (FRAP and ABTS Assays)

2.1.3. Untargeted Phenolic Profiling by UHPLC-HRMS Approach

2.1.4. Antimicrobial Activity

2.2. Coating Preparation

2.3. Migration Test

2.3.1. Overall Migration

2.3.2. Migration of Bioactive Compounds

2.4. Antimicrobial Activity of Coatings

2.5. Statistical Analysis

3. Results

3.1. Bioactivity of Olive Leaf Extract

3.1.1. Total Phenolic Content and Antioxidant Capacity

3.1.2. Untargeted Phenolic Profiling by UHPLC-HRMS Approach

3.1.3. Antimicrobial Activity

3.2. Migration Test

3.2.1. Overall Migration

3.2.2. Migration of Bioactive Compounds and Multivariate Statistical Discrimination

3.3. Antimicrobial Activity

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yildirim, S.; Röcker, B.; Pettersen, M.K.; Nilsen-Nygaard, J.; Ayhan, Z.; Rutkaite, R.; Radusin, T.; Suminska, P.; Marcos, B.; Coma, V. Active Packaging Applications for Food. Compr. Rev. Food Sci. Food Saf. 2018, 17, 165–199. [Google Scholar] [CrossRef] [PubMed]

- Salles Barone, A.; Matheus, J.R.V.; De Souza, T.S.P.; Moreira, R.F.A.; Fai, A.E.C. Green-Based Active Packaging: Opportunities beyond COVID-19, Food Applications, and Perspectives in Circular Economy—A Brief Review. Compr. Rev. Food Sci. Food Saf. 2021, 20, 4881–4905. [Google Scholar] [CrossRef] [PubMed]

- Fu, Y.; Dudley, E.G. Antimicrobial-Coated Films as Food Packaging: A Review. Compr. Rev. Food Sci. Food Saf. 2021, 20, 3404–3437. [Google Scholar] [CrossRef] [PubMed]

- Mulla, M.; Ahmed, J.; Al-Attar, H.; Castro-Aguirre, E.; Arfat, Y.A.; Auras, R. Antimicrobial Efficacy of Clove Essential Oil Infused into Chemically Modified LLDPE Film for Chicken Meat Packaging. Food Control 2017, 73, 663–671. [Google Scholar] [CrossRef]

- Azlin-Hasim, S.; Cruz-Romero, M.C.; Morris, M.A.; Cummins, E.; Kerry, J.P. Spray Coating Application for the Development of Nanocoated Antimicrobial Low-Density Polyethylene Films to Increase the Shelf Life of Chicken Breast Fillets. Food Sci. Technol. Int. 2018, 24, 688–698. [Google Scholar] [CrossRef] [PubMed]

- Bastarrachea, L.J.; Wong, D.E.; Roman, M.J.; Lin, Z.; Goddard, J.M. Active Packaging Coatings. Coatings 2015, 5, 771–791. [Google Scholar] [CrossRef]

- Shahidi, F.; Varatharajan, V.; Oh, W.Y.; Peng, H. Phenolic Compounds in Agri-Food by-Products, Their Bioavailability and Health Effects. J. Food Bioact. 2019, 5, 57–119. [Google Scholar] [CrossRef]

- Rojas, A.; Velásquez, E.; Vidal, C.P.; Guarda, A.; Galotto, M.J.; de Dicastillo, C.L. Active PLA Packaging Films: Effect of Processing and the Addition of Natural Antimicrobials and Antioxidants on Physical Properties, Release Kinetics, and Compostability. Antioxidants 2021, 10, 1976. [Google Scholar] [CrossRef] [PubMed]

- Espeso, J.; Isaza, A.; Lee, J.Y.; Sörensen, P.M.; Jurado, P.; Avena-Bustillos, R.D.J.; Olaizola, M.; Arboleya, J.C. Olive Leaf Waste Management. Front. Sustain. Food Syst. 2021, 5, 660582. [Google Scholar] [CrossRef]

- Borjan, D.; Leitgeb, M.; Knez, Ž.; Hrnčič, M.K. Microbiological and Antioxidant Activity of Phenolic Compounds in Olive Leaf Extract. Molecules 2020, 25, 5946. [Google Scholar] [CrossRef] [PubMed]

- Martiny, T.R.; Raghavan, V.; de Moraes, C.C.; da Rosa, G.S.; Dotto, G.L. Bio-Based Active Packaging: Carrageenan Film with Olive Leaf Extract for Lamb Meat Preservation. Foods 2020, 9, 1759. [Google Scholar] [CrossRef] [PubMed]

- Amaro-Blanco, G.; Delgado-Adámez, J.; Martín, M.J.; Ramírez, R. Active Packaging Using an Olive Leaf Extract and High Pressure Processing for the Preservation of Sliced Dry-Cured Shoulders from Iberian Pigs. Innov. Food Sci. Emerg. Technol. 2018, 45, 1–9. [Google Scholar] [CrossRef]

- Cejudo Bastante, C.; Casas Cardoso, L.; Fernández Ponce, M.T.; Mantell Serrano, C.; Martínez de la Ossa-Fernández, E.J. Characterization of Olive Leaf Extract Polyphenols Loaded by Supercritical Solvent Impregnation into PET/PP Food Packaging Films. J. Supercrit. Fluids 2018, 140, 196–206. [Google Scholar] [CrossRef]

- Grabska-Zielińska, S.; Gierszewska, M.; Olewnik-Kruszkowska, E.; Bouaziz, M. Polylactide Films with the Addition of Olive Leaf Extract—Physico-Chemical Characterization. Materials 2021, 14, 7623. [Google Scholar] [CrossRef] [PubMed]

- Bassani, A.; Fiorentini, C.; Vadivel, V.; Moncalvo, A.; Spigno, G. Implementation of Auto-Hydrolysis Process for the Recovery of Antioxidants and Cellulose from Wheat Straw. Appl. Sci. 2020, 10, 6112. [Google Scholar] [CrossRef]

- Fiorentini, C.; Garrido, G.D.; Bassani, A.; Cortimiglia, C.; Zaccone, M.; Montalbano, L.; Martinez-Nogues, V.; Cocconcelli, P.S.; Spigno, G. Citrus Peel Extracts for Industrial-Scale Production of Bio-Based Active Food Packaging. Foods 2022, 11, 30. [Google Scholar] [CrossRef]

- UNI EN 1186-1:2003; Materials and Articles in Contact with Foodstuffs—Plastics—Guide to the Selection of Conditions and Test Methods for Overall Migration. 2003. Available online: https://img.21food.cn/img/biaozhun/20090815/187/11183625.pdf (accessed on 23 April 2024).

- ISO 22196; Measurement of Antibacterial Activity on Plastics and Other Non-Porous Surfaces. International Standards Organization: Geneva, Switzerland, 2011.

- Pang, Z.; Chong, J.; Zhou, G.; De Lima Morais, D.A.; Chang, L.; Barrette, M.; Gauthier, C.; Jacques, P.É.; Li, S.; Xia, J. MetaboAnalyst 5.0: Narrowing the Gap between Raw Spectra and Functional Insights. Nucleic Acids Res. 2021, 49, W388–W396. [Google Scholar] [CrossRef] [PubMed]

- Rocchetti, G.; Rebecchi, A.; Dallolio, M.; Braceschi, G.; Domínguez, R.; Dallolio, G.; Trevisan, M.; Lorenzo, J.M.; Lucini, L. Changes in the Chemical and Sensory Profile of Ripened Italian Salami Following the Addition of Different Microbial Starters. Meat Sci. 2021, 180, 108584. [Google Scholar] [CrossRef] [PubMed]

- Shofinita, D.; Feng, S.; Langrish, T.A.G. Comparing Yields from the Extraction of Different Citrus Peels and Spray Drying of the Extracts. Adv. Powder Technol. 2015, 26, 1633–1638. [Google Scholar] [CrossRef]

- Romero-Márquez, J.M.; Navarro-Hortal, M.D.; Forbes-Hernández, T.Y.; Varela-López, A.; Puentes, J.G.; Pino-García, R.D.; Sánchez-González, C.; Elio, I.; Battino, M.; García, R.; et al. Exploring the Antioxidant, Neuroprotective, and Anti-Inflammatory Potential of Olive Leaf Extracts from Spain, Portugal, Greece, and Italy. Antioxidants 2023, 12, 1538. [Google Scholar] [CrossRef]

- Cifá, D.; Skrt, M.; Pittia, P.; Di Mattia, C.; Poklar Ulrih, N. Enhanced Yield of Oleuropein from Olive Leaves Using Ultrasound-Assisted Extraction. Food Sci. Nutr. 2018, 6, 1128–1137. [Google Scholar] [CrossRef] [PubMed]

- Giacometti, J.; Milovanović, S.; Jurc\ĭć Momc\ĭlović, D.; Bubonja-S\ŏnje, M. Evaluation of Antioxidant Activity of Olive Leaf Extract Obtained by Ultrasound-Assisted Extraction and Their Antimicrobial Activity against Bacterial Pathogens from Food. Int. J. Food Sci. Technol. 2021, 56, 4843–4850. [Google Scholar] [CrossRef]

- Herrero, M.; Gerber, P.; Vellinga, T.; Garnett, T.; Leip, A.; Opio, C.; Westhoek, H.J.; Thornton, P.K.; Olesen, J.; Hutchings, N.; et al. Livestock and Greenhouse Gas Emissions: The Importance of Getting the Numbers Right. Anim. Feed Sci. Technol. 2011, 166–167, 779–782. [Google Scholar] [CrossRef]

- Apostolakis, A.; Grigorakis, S.; Makris, D.P. Optimisation and Comparative Kinetics Study of Polyphenol Extraction from Olive Leaves (Olea Europaea) Using Heated Water/Glycerol Mixtures. Sep. Purif. Technol. 2014, 128, 89–95. [Google Scholar] [CrossRef]

- Ghasemi, S.; Koohi, D.E.; Emmamzadehhashemi, M.S.B.; Khamas, S.S.; Moazen, M.; Hashemi, A.K.; Amin, G.; Golfakhrabadi, F.; Yousefi, Z.; Yousefbeyk, F. Investigation of Phenolic Compounds and Antioxidant Activity of Leaves Extracts from Seventeen Cultivars of Iranian Olive (Olea europaea L.). J. Food Sci. Technol. 2018, 55, 4600–4607. [Google Scholar] [CrossRef] [PubMed]

- Moudache, M.; Colon, M.; Nerín, C.; Zaidi, F. Phenolic Content and Antioxidant Activity of Olive By-Products and Antioxidant Film Containing Olive Leaf Extract. Food Chem. 2016, 212, 521–527. [Google Scholar] [CrossRef]

- Abaza, L.; Taamalli, A.; Arráez-Román, D.; Segura-Carretero, A.; Fernández-Gutierrérez, A.; Zarrouk, M.; Youssef, N. Ben Changes in Phenolic Composition in Olive Tree Parts According to Development Stage. Food Res. Int. 2017, 100, 454–461. [Google Scholar] [CrossRef] [PubMed]

- Pereira, A.P.; Ferreira, I.C.F.R.; Marcelino, F.; Valentão, P.; Andrade, P.B.; Seabra, R.; Estevinho, L.; Bento, A.; Pereira, J.A. Phenolic Compounds and Antimicrobial Activity of Olive (Olea europaea L. Cv. Cobrançosa) Leaves. Molecules 2007, 12, 1153–1162. [Google Scholar] [CrossRef] [PubMed]

- Thielmann, J.; Kohnen, S.; Hauser, C. Antimicrobial Activity of Olea Europaea Linné Extracts and Their Applicability as Natural Food Preservative Agents. Int. J. Food Microbiol. 2017, 251, 48–66. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; McKeever, L.C.; Malik, N.S.A. Assessment of the Antimicrobial Activity of Olive Leaf Extract against Foodborne Bacterial Pathogens. Front. Microbiol. 2017, 8, 113. [Google Scholar] [CrossRef] [PubMed]

- Qian, W.; Liu, M.; Fu, Y.; Zhang, J.; Liu, W.; Li, J.; Li, X.; Li, Y.; Wang, T. Antimicrobial Mechanism of Luteolin against Staphylococcus Aureus and Listeria Monocytogenes and Its Antibiofilm Properties. Microb. Pathog. 2020, 142, 104056. [Google Scholar] [CrossRef] [PubMed]

- Nerin, C.; Silva, F.; Manso, S.; Becerril, R. The Downside of Antimicrobial Packaging: Migration of Packaging Elements into Food. Antimicrob. Food Packag. 2016, 81–93. [Google Scholar] [CrossRef]

| Coating Formulation | Overall Migration (mg/dm2) | ||

|---|---|---|---|

| Simulant A | Simulant B | Simulant D2 | |

| Chitosan | 34.31 ± 3.44 aA | 34.93 ± 1.86 aA | 4.31 ± 0.36 bA |

| Alginate | 36.32 ± 5.41 aA | 44.24 ± 2.31 bB | 11.20 ± 3.26 cB |

| Metylcellulose | 37.07 ± 2.72 aA | 30.90 ± 1.39 bC | 9.86 ± 2.11 cB |

| Control (uncoated) | 0.56 ± 0.48 aB | 3.19 ± 0.73 bD | 2.01 ± 0.27 cA |

| Food Simulant | Sample | Phenolic Class Equivalent (µg Std Eq./L) | ||||||

|---|---|---|---|---|---|---|---|---|

| Anthocyanins | Flavones and Flavonoids | Flavanols | Flavonols | Phenolic Acids | Stilbenes | Tyrosol Derivatives | ||

| A | MC | 197.6 ± 35.8 | 484.9 ± 86.7 | 571.5 ± 30.6 | 31.4 ± 2.8 | 1588.6 ± 151.7 | 89.3 ± 2.7 | 9862.3 ± 722.3 |

| CT | 364.6 ± 19.3 | 935.9 ± 58.2 | 662.8 ± 45.2 | 66.7 ± 4.7 | 2756.8 ± 150.5 | 115.2 ± 19.6 | 18,337.2 ± 1659.2 | |

| ALG | 226.1 ± 10.5 | 439.5 ± 9.1 | 243.1 ± 22.4 | 29.1 ± 2.1 | 1354.6 ± 190.0 | 91.8 ± 5.3 | 8732.5 ± 207.4 | |

| B | MC | 197.5 ± 28.2 | 463.5 ± 23.2 | 336.5 ± 54.6 | 32.8 ± 4.2 | 1611.5 ± 167.1 | 120.9 ± 6.8 | 7702.8 ± 333.1 |

| CT | 376.4 ± 29.2 | 976.0 ± 52.3 | 553.9 ± 133.4 | 68.3 ± 12.9 | 2286.7 ± 91.4 | 106.3 ± 14.1 | 16,816.5 ± 709.0 | |

| ALG | 240.8 ± 30.4 | 449.9 ± 43.6 | 308.1 ± 30.0 | 27.1 ± 1.5 | 1335.0 ± 90.6 | 102.8 ± 11.4 | 7635.3 ± 810.9 | |

| Food Simulant | Coated PLA Film | Total Phenolic Eq. Conc. [mg Eq./L] | Migrated Active Compounds [%] |

|---|---|---|---|

| A | Methylcellulose | 12.8 ± 0.7 | 25.79 ± 1.51 aA |

| Chitosan | 23.2 ± 1.8 | 46.72 ± 3.61 bB | |

| Alginate | 11.1 ± 0.2 | 22.35 ± 0.44 aA | |

| B | Metylcellulose | 10.5 ± 0.6 | 21.04 ± 1.12 aA |

| Chitosan | 21.2 ± 0.9 | 42.59 ± 1.86 bB | |

| Alginate | 10.1 ± 1.0 | 20.30 ± 1.96 aA |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fiorentini, C.; Leni, G.; de Apodaca, E.D.; Fernández-de-Castro, L.; Rocchetti, G.; Cortimiglia, C.; Spigno, G.; Bassani, A. Development of Coated PLA Films Containing a Commercial Olive Leaf Extract for the Food Packaging Sector. Antioxidants 2024, 13, 519. https://0-doi-org.brum.beds.ac.uk/10.3390/antiox13050519

Fiorentini C, Leni G, de Apodaca ED, Fernández-de-Castro L, Rocchetti G, Cortimiglia C, Spigno G, Bassani A. Development of Coated PLA Films Containing a Commercial Olive Leaf Extract for the Food Packaging Sector. Antioxidants. 2024; 13(5):519. https://0-doi-org.brum.beds.ac.uk/10.3390/antiox13050519

Chicago/Turabian StyleFiorentini, Cecilia, Giulia Leni, Elena Díaz de Apodaca, Laura Fernández-de-Castro, Gabriele Rocchetti, Claudia Cortimiglia, Giorgia Spigno, and Andrea Bassani. 2024. "Development of Coated PLA Films Containing a Commercial Olive Leaf Extract for the Food Packaging Sector" Antioxidants 13, no. 5: 519. https://0-doi-org.brum.beds.ac.uk/10.3390/antiox13050519