Evaluation of Local Mechanical and Chemical Properties via AFM as a Tool for Understanding the Formation Mechanism of Pulsed UV Laser-Nanoinduced Patterns on Azo-Naphthalene-Based Polyimide Films

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material

2.2. Molecular Simulations

2.3. Laser Patterning

2.4. Measurements

3. Results and Discussion

3.1. AFM Nanoscale Morphological Analysis

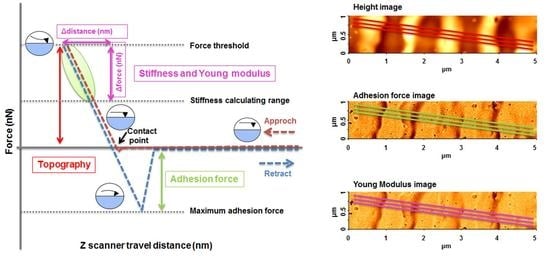

3.2. Nanomechanical Characterization Using AFM PinPoint Mode

3.3. Evaluation of the Local Chemical Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B

Appendix C

References

- Ghosh, M.K. Polyimides: Fundamentals and Applications; Ghosh, M.K., Mittal, K.L., Eds.; Marcel Dekker: New York, NY, USA, 1996; ISBN 0-8247-9466-4. [Google Scholar]

- Wang, D.H.; Lee, K.M.; Yu, Z.; Koerner, H.; Vaia, R.A.; White, T.J.; Tan, L.-S. Photomechanical Response of Glassy Azobenzene Polyimide Networks. Macromolecules 2011, 44, 3840–3846. [Google Scholar] [CrossRef]

- Schab-Balcerzak, E.; Siwy, M.; Jarzabek, B.; Kozanecka-Szmigiel, A.; Switkowski, K.; Pura, B. Post and prepolymerization strategies to develop novel photochromic poly(esterimide)s. J. Appl. Polym. Sci. 2011, 120, 631–643. [Google Scholar] [CrossRef]

- Yaroshchuk, O.; Reznikov, Y. Photoalignment of liquid crystals: Basics and current trends. J. Mater. Chem. 2012, 22, 286–300. [Google Scholar] [CrossRef]

- Yu, Y.; Nakano, M.; Shishido, A.; Shiono, T.; Ikeda, T. Effect of Cross-linking Density on Photoinduced Bending Behavior of Oriented Liquid-Crystalline Network Films Containing Azobenzene. Chem. Mater. 2004, 16, 1637–1643. [Google Scholar] [CrossRef]

- Nikolova, L.; Ramanujam, P. Polarization Holography; Cambridge University Press: Cambridge, UK, 2009; ISBN 9781498775809. [Google Scholar]

- Todorov, T.; Nikolova, L.; Tomova, N. Polarization holography 1: A new high-efficiency organic material with reversible photoinduced birefringence. Appl. Opt. 1984, 23, 4309–4312. [Google Scholar] [CrossRef] [PubMed]

- Todorov, T.; Nikolova, L.; Tomova, N. Polarization holography 2: Polarization holographic gratings in photoanisotropic materials with and without intrinsic birefringence. Appl. Opt. 1984, 23, 4588–4591. [Google Scholar] [CrossRef] [PubMed]

- Schab-Balcerzak, E.; Sobolewska, A.; Miniewicz, A. Comparative studies of newly synthesized azo-dyes bearing poly(esterimide)s with their poly(etherimide) analogues. Light-induced optical anisotropy. Opt. Mater. 2008, 31, 405–411. [Google Scholar] [CrossRef]

- Sava, I.; Sacarescu, L.; Stoica, I.; Apostol, I.; Damian, V.; Hurduc, N. Photochromic properties of polyimide and polysiloxane azopolymers. Polym. Int. 2009, 58, 163–170. [Google Scholar] [CrossRef]

- Sava, I.; Hurduc, N.; Sacarescu, L.; Apostol, I.; Damian, V. Study of the nanostructuration capacity of some azopolymers with rigid or flexible chains. High Perform. Polym. 2013, 25, 13–24. [Google Scholar] [CrossRef]

- Sava, I.; Resmerita, A.-M.; Lisa, G.; Damian, V.; Hurduc, N. Synthesis and photochromic behavior of new polyimides containing azobenzene side groups. Polymer. 2008, 49, 1475–1482. [Google Scholar] [CrossRef]

- Sava, I.; Burescu, A.; Stoica, I.; Musteata, V.; Cristea, M.; Mihaila, I.; Pohoata, V.; Topala, I. Properties of some azo-copolyimide thin films used in the formation of photoinduced surface relief gratings. RSC Adv. 2015, 5, 10125–10133. [Google Scholar] [CrossRef]

- Bujak, K.; Sava, I.; Stoica, I.; Tiron, V.; Topala, I.; Węgłowski, R.; Schab-Balcerzak, E.; Konieczkowska, J. Photoinduced properties of “T-type” polyimides with azobenzene or azopyridine moieties. Eur. Polym. J. 2020, 126, 109563. [Google Scholar] [CrossRef]

- Schab-Balcerzak, E.; Sapich, B.; Stumpe, J. Photoinduced optical anisotropy in new poly (amide imide) s with azobenzene units. Polymer 2005, 46, 49–59. [Google Scholar] [CrossRef]

- Schab-Balcerzak, E.; Sobolewska, A.; Miniewicz, A.; Jurusik, J.; Jarzabek, B. Photoinduced Holographic Gratings in Azobenzene-Functionalized Poly(amideimide)s. Polym. J. 2007, 39, 659–669. [Google Scholar] [CrossRef] [Green Version]

- Konieczkowska, J.; Schab-Balcerzak, E.; Siwy, M.; Switkowski, K.; Kozanecka-Szmigiel, A. Large and highly stable photoinduced birefringence in poly(amideimide)s with two azochromophores per structural unit. Opt. Mater. 2015, 39, 199–206. [Google Scholar] [CrossRef]

- Konieczkowska, J.; Janeczek, H.; Malecki, J.G.; Schab-Balcerzak, E. The comprehensive approach towards study of (azo)polymers fragility parameter: Effect of architecture, intra- and intermolecular interactions and backbone conformation. Eur. Polym. J. 2018, 109, 489–498. [Google Scholar] [CrossRef]

- Bujak, K.; Kozanecka-Szmigiel, A.; Schab-Balcerzak, E.; Konieczkowska, J. Azobenzene Functionalized “T-Type” Poly (Amide Imide) s vs. Guest-Host Systems—A Comparative Study of Structure-Property Relations. Materials 2020, 13, 1912. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hurduc, N.; Donose, B.C.; Macovei, A.; Paius, C.; Ibanescu, C.; Scutaru, D.; Hamel, M.; Branza-Nichita, N.; Rocha, L. Direct observation of athermal photofluidisation in azo-polymer films. Soft Matter 2014, 10, 4640–4647. [Google Scholar] [CrossRef] [PubMed]

- Hurduc, N.; Donose, B.C.; Rocha, L.; Ibanescu, C.; Scutaru, D. Azo-polymers photofluidisation—A transient state of matter emulated by molecular motors. RSC Adv. 2016, 6, 27087–27093. [Google Scholar] [CrossRef]

- Stoica, I.; Epure, L.; Sava, I.; Damian, V.; Hurduc, N. An atomic force microscopy statistical analysis of laser-induced azo-polyimide periodic tridimensional nanogrooves. Microsc. Res. Tech. 2013, 76, 914–923. [Google Scholar] [CrossRef]

- Sava, I.; Stoica, I.; Mihaila, I.; Pohoata, V.; Topala, I.; Stoian, G.; Lupu, N. Nanoscale analysis of laser-induced surface relief gratings on azo-copolyimide films before and after gold coating. Polym. Test. 2018, 72, 407–415. [Google Scholar] [CrossRef]

- Damian, V.; Resmerita, E.; Stoica, I.; Ibanescu, C.; Sacarescu, L.; Rocha, L.; Hurduc, N. Surface relief gratings induced by pulsed laser irradiation in low glass-transition temperature azopolysiloxanes. J. Appl. Polym. Sci. 2014, 131, 41015. [Google Scholar] [CrossRef] [Green Version]

- Pederzoli, M.; Pittner, J.; Barbatti, M.; Lischka, H. Nonadiabatic Molecular Dynamics Study of the cis—Trans Photoisomerization of Azobenzene Excited to the S 1 State. J. Phys. Chem. A 2011, 115, 11136–11143. [Google Scholar] [CrossRef]

- Ootani, Y.; Satoh, K.; Nakayama, A.; Noro, T.; Taketsugu, T. Ab initio molecular dynamics simulation of photoisomerization in azobenzene in the nπ∗ state. J. Chem. Phys. 2009, 131, 194306. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Biswas, M.; Burghardt, I. Azobenzene Photoisomerization-Induced Destabilization of B-DNA. Biophys. J. 2014, 107, 932–940. [Google Scholar] [CrossRef] [Green Version]

- Wei-Guang Diau, E. A New Trans-to-Cis Photoisomerization Mechanism of Azobenzene on the S 1 (n,π*) Surface. J. Phys. Chem. A 2004, 108, 950–956. [Google Scholar] [CrossRef]

- Chami, F.; Wilson, M.R. Molecular Order in a Chromonic Liquid Crystal: A Molecular Simulation Study of the Anionic Azo Dye Sunset Yellow. J. Am. Chem. Soc. 2010, 132, 7794–7802. [Google Scholar] [CrossRef]

- Böckmann, M.; Peter, C.; Site, L.D.; Doltsinis, N.L.; Kremer, K.; Marx, D. Atomistic Force Field for Azobenzene Compounds Adapted for QM/MM Simulations with Applications to Liquids and Liquid Crystals. J. Chem. Theory Comput. 2007, 3, 1789–1802. [Google Scholar] [CrossRef] [PubMed]

- Carlescu, I.; Simion, A.; Epure, E.L.; Lisa, G.; Scutaru, D. Self-assembled star-shaped liquid crystals based on 1,3,5-trihydroxybenzene with pendant alkyloxylated azobenzene arms. Liq. Cryst. 2020, 47, 1852–1862. [Google Scholar] [CrossRef]

- Georgiev, A.; Kostadinov, A.; Ivanov, D.; Dimov, D.; Stoyanov, S.; Nedelchev, L.; Nazarova, D.; Yancheva, D. Synthesis, spectroscopic and TD-DFT quantum mechanical study of azo-azomethine dyes. A laser induced trans-cis-trans photoisomerization cycle. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2018, 192, 263–274. [Google Scholar] [CrossRef]

- Epure, E.-L.; Vasiliu, T.; Hurduc, N.; Neamțu, A. Molecular modeling study concerning the self-assembly capacity of some photosensitive amphiphilic polysiloxanes. J. Mol. Liq. 2020, 300, 112298. [Google Scholar] [CrossRef]

- Xia, S.-H.; Cui, G.; Fang, W.-H.; Thiel, W. How Photoisomerization Drives Peptide Folding and Unfolding: Insights from QM/MM and MM Dynamics Simulations. Angew. Chem. Int. Ed. 2016, 55, 2067–2072. [Google Scholar] [CrossRef] [Green Version]

- Böckmann, M.; Doltsinis, N.L. Towards understanding photomigration: Insights from atomistic simulations of azopolymer films explicitly including light-induced isomerization dynamics. J. Chem. Phys. 2016, 145, 154701. [Google Scholar] [CrossRef] [PubMed]

- Pawlik, G.; Mitus, A.C. Photoinduced Mass Transport in Azo-Polymers in 2D: Monte Carlo Study of Polarization Effects. Materials 2020, 13, 4724. [Google Scholar] [CrossRef]

- Juan, M.L.; Plain, J.; Bachelot, R.; Royer, P.; Gray, S.K.; Wiederrecht, G.P. Stochastic model for photoinduced surface relief grating formation through molecular transport in polymer films. Appl. Phys. Lett. 2008, 93, 153304. [Google Scholar] [CrossRef]

- Stiller, B.; Karageorgiev, P.; Geue, T.; Morawetz, K.; Saphiannikova, M.; Mechau, N.; Neher, D. Optically induced mass transport studied by scanning near-field optical - and atomic force microscopy. Phys. Low Dimens. Struct. 2004, 1/2, 129–138. [Google Scholar]

- Sadegh Hassani, S.; Daraee, M.; Sobat, Z. Application of atomic force microscopy in adhesion force measurements. J. Adhes. Sci. Technol. 2021, 35, 221–241. [Google Scholar] [CrossRef]

- Krotil, H.-U.; Stifter, T.; Waschipky, H.; Weishaupt, K.; Hild, S.; Marti, O. Pulsed force mode: A new method for the investigation of surface properties. Surf. Interface Anal. 1999, 27, 336–340. [Google Scholar] [CrossRef]

- Exploring Nanomechanical Properties of Materials with Atomic Force Microscopy, NT-MDT Spectrum Instruments Application Note no. 085. 2017. Available online: https://www.ntmdt-si.com/resources/applications/exploring-nanomechanical-properties-of-materials-with-atomic-force-microscopy (accessed on 22 February 2021).

- Expanding Atomic Force Microscopy with HybriD Mode Imaging, NT-MDT Spectrum Instruments Application Note no. 087/2017. Available online: https://www.ntmdt-si.com/resources/applications/expanding-atomic-force-microscopy-with-hybrid-mode-imaging (accessed on 22 February 2021).

- Quantitative Nanomechanical Measurements in HybriD Mode Atomic Force Microscopy, NT-MDT Spectrum Instruments Application Note no. 090. 2017. Available online: https://www.ntmdt-si.com/resources/applications/quantitative-nanomechanical-measurements-in-hybrid-mode-atomic-force-microscopy (accessed on 22 February 2021).

- Park PinPointTM Mode. Available online: https://parksystems.com/files/pinpoint_mode_brochure.pdf (accessed on 22 February 2021).

- Constantin, C.-P.; Sava, I.; Damaceanu, M.-D. Structural Chemistry-Assisted Strategy toward Fast Cis–Trans Photo/Thermal Isomerization Switch of Novel Azo-Naphthalene-Based Polyimides. Macromolecules 2021, 54, 1517–1538. [Google Scholar] [CrossRef]

- Materials Studio 4.0; DMol3, Forcite and Amorphous Cell Module; Accelrys Software Inc.: San Diego, CA, USA, 2005.

- Miniewicz, A.; Sahraoui, B.; Schab-Balcerzak, E.; Sobolewska, A.; Mitus, A.C.; Kajzar, F. Pulsed-Laser Grating Recording in Organic Materials Containig Azobenzene Derivatives. Nonlinear Opt. Quantum Opt. 2006, X, 1–8. [Google Scholar]

- Kim, S.; Park, S.; Lee, W.; Kwon, O.; Kim, S.U.; Choi, Y.; Yoon, M.; Park, J.; Kim, Y. Origin of macroscopic adhesion in organic light-emitting diodes analyzed at different length scales. Sci. Rep. 2018, 8, 1–7. [Google Scholar] [CrossRef]

- Othonos, A.; Kalli, K.; Pureur, D.; Mugnier, A. Fibre Bragg Gratings. In Wavelength Filters in Fibre Optics; Springer: Berlin Germany, 2006; Volume 123, pp. 189–269. ISBN 3540317694. [Google Scholar]

- Lagugné-Labarthet, F.; Buffeteau, T.; Sourisseau, C. Molecular orientations in azopolymer holographic diffraction gratings as studied by Raman confocal microspectroscopy. J. Phys. Chem. B 1998, 102, 5754. [Google Scholar] [CrossRef]

- Stoica, I.; Hurduc, N. Structuring of Polymer Surfaces via Laser Irradiation as a Tool for Micro-and Nanotechnologies. In Electromagnetic Radiation in Analysis and Design of Organic Materials; Dorohoi, D.O., Barzic, A.I., Aflori, M., Eds.; CRC Press; Taylor & Francis Group: Boca Raton, FL, USA, 2017; Chapter 12; pp. 191–206. ISBN 9781498775809. [Google Scholar]

- Barrett, C.J.; Natansohn, A.L.; Rochon, P.L. Mechanism of Optically Inscribed High-Efficiency Diffraction Gratings in Azo Polymer Films. J. Phys. Chem. 1996, 100, 8836–8842. [Google Scholar] [CrossRef]

- Wu, X.; Ngan Nguyen, T.T.; Ledoux-Rak, I.; Thanh Nguyen, C.; Diep, N. Optically Accelerated Formation of One- and Two-Dimensional Holographic Surface Relief Gratings on DR1/PMMA. In Holography—Basic Principles and Contemporary Applications; InTech: Rijeka, Croatia, 2013. [Google Scholar]

- Wu, X. Fabrication of 1D, 2D and 3D polymer-based periodic structures by mass transport effect. Ph.D. Thesis, École Normale Supérieure de Cachan—ENS Cachan, Paris, France, 2013. [Google Scholar]

- Viswanathan, N.K.; Balasubramanian, S.; Li, L.; Kumar, J.; Tripathy, S.K. Surface-Initiated Mechanism for the Formation of Relief Gratings on Azo-Polymer Films. J. Phys. Chem. B 1998, 102, 6064. [Google Scholar] [CrossRef]

- Sdr Parameters and Its Applications in Characterizing Surface Data. Available online: https://www.azonano.com/article.aspx?ArticleID=5137 (accessed on 2 March 2021).

- ISO 25178-2:2012 Geometrical Product Specifications (GPS)—Surface Texture: Areal—Part 2: Terms, Definitions and Surface Texture Parameters. 2012. Available online: https://www.iso.org/standard/42785.html (accessed on 21 March 2021).

- Stoica, I.; Barzic, A.I.; Hulubei, C.; Timpu, D. Statistical analysis on morphology development of some semialicyclic polyimides using atomic force microscopy. Microsc. Res. Tech. 2013, 76, 503–513. [Google Scholar] [CrossRef] [PubMed]

- Reifenberger, R. Fundamentals of Atomic Force Microscopy Part I: Foundations; Lessons from Nanoscience: A Lecture Notes Series; World Scientific Publishing: Singapore, 2015; Volume 4, ISBN 978-981-4630-34-4. [Google Scholar]

- Park Systems Introduces PinPointTM Nanomechanical Mode to Characterize Nano Mechanical Properties of Materials and Biological Cells. Available online: https://parksystems.com/company/news/press-release/450-nanomechanical-mode-to-characterize-nano-mechanical (accessed on 21 March 2021).

- Collagen Fibrils Imaging in Liquid Using Park NX10 Atomic Force Microscope PinPointTM Nanomechanical Mode; Park Atomic Force Microscopy; Application note #4. Available online: https://parksystems.com/applications/life-science/micro-and-molecular-biology/607-collagen-fibrils-imaging-using-park-nx10-atomic-force-microscope-pinpoint-nanomechanical-mode (accessed on 14 March 2021).

- Cao, X.; Gan, X.; Peng, Y.; Wang, Y.; Zeng, X.; Lang, H.; Deng, J.; Zou, K. An ultra-low frictional interface combining FDTS SAMs with molybdenum disulfide. Nanoscale 2018, 10, 378–385. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lin, Y.C.; Peng, X.Y.; Wang, L.C.; Lin, Y.L.; Wu, C.H.; Liang, S.C. Residual stress in CIGS thin film solar cells on polyimide: Simulation and experiments. J. Mater. Sci. Mater. Electron. 2014, 25, 461–465. [Google Scholar] [CrossRef]

- Blösch, P.; Güttler, D.; Chirila, A.; Tiwari, A.N. Optimization of Ti/TiN/Mo back contact properties for Cu (In,Ga)Se 2 solar cells on polyimide foils. Thin Solid Film. 2011, 519, 7453–7457. [Google Scholar] [CrossRef]

- Yadavalli, N.S. Advances in Experimental Methods to Probe Surface Relief Grating Formation Mechanism in Photosensitive Materials. Ph.D. Thesis, University of Potsdam, Postdam, Germany, 2014. [Google Scholar]

- Zong, C.; Zhao, Y.; Ji, H.; Han, X.; Xie, J.; Wang, J.; Cao, Y.; Jiang, S.; Lu, C. Tuning and Erasing Surface Wrinkles by Reversible Visible-Light-Induced Photoisomerization. Angew. Chem. Int. Ed. 2016, 55, 3931–3935. [Google Scholar] [CrossRef]

- Bian, S.; Williams, J.M.; Kim, D.Y.; Li, L.; Balasubramanian, S.; Kumar, J.; Tripathy, S. Photoinduced surface deformations on azobenzene polymer films. J. Appl. Phys. 1999, 86, 4498–4508. [Google Scholar] [CrossRef]

- Srikhirin, T.; Laschitsch, A.; Neher, D.; Johannsmann, D. Light-induced softening of azobenzene dye-doped polymer films probed with quartz crystal resonators. Appl. Phys. Lett. 2000, 77, 963–965. [Google Scholar] [CrossRef]

- Mechau, N.; Neher, D.; Börger, V.; Menzel, H.; Urayama, K. Optically driven diffusion and mechanical softening in azobenzene polymer layers. Appl. Phys. Lett. 2003, 81, 4715–4717. [Google Scholar] [CrossRef]

- Mechau, N.; Saphiannikova, M.; Neher, D. Dielectric and mechanical properties of azobenzene polymer layers under visible and ultraviolet irradiation. Macromolecules 2005, 38, 3894–3902. [Google Scholar] [CrossRef]

- Gherab, K.N.; Gatri, R.; Hank, Z.; Dick, B.; Kutta, R.J.; Winter, R.; Luc, J.; Sahraoui, B.; Fillaut, J.L. Design and photoinduced surface relief grating formation of photoresponsive azobenzene based molecular materials with ruthenium acetylides. J. Mater. Chem. 2010, 20, 2858–2864. [Google Scholar] [CrossRef] [Green Version]

- Wang, X. Azo Polymers: Synthesis, Functions and Applications; Springer: Berlin, Germany, 2017; ISBN 9783662534229. [Google Scholar]

- Di Florio, G.; Bründermann, E.; Yadavalli, N.S.; Santer, S.; Havenith, M. Graphene Multilayer as Nanosized Optical Strain Gauge for Polymer Surface Relief Gratings. Nano Lett. 2014, 14, 5754–5760. [Google Scholar] [CrossRef]

- Di Florio, G.; Bründermann, E.; Yadavalli, N.S.; Santer, S.; Havenith, M. Polarized 3D Raman and nanoscale near-field optical microscopy of optically inscribed surface relief gratings: Chromophore orientation in azo-doped polymer films. Soft Matter 2014, 10, 1544. [Google Scholar] [CrossRef]

| Parameter | Sample | |||

|---|---|---|---|---|

| AzoPI 10/10 | AzoPI 10/100 | AzoPI 45/10 | AzoPI 45/100 | |

| Height parameters | ||||

| Sq (nm) | 0.4 | 0.732 | 16.159 | 28.723 |

| Shape parameters | ||||

| Ssk | 0.466 | −0.284 | 0.762 | 0.343 |

| Sku | 5.466 | 3.061 | 2.354 | 3.193 |

| Spatial parameters | ||||

| Stdi | 0.388 | 0.418 | 0.193 | 0.407 |

| Hybrid parameters | ||||

| Sdr (%) | 0.00542 | 0.00981 | 1.496 | 5.342 |

| Functional indexes | ||||

| Sbi | 0.113 | 0.308 | 0.794 | 0.429 |

| Sci | 1.464 | 1.346 | 1.839 | 1.671 |

| Svi | 0.0855 | 0.131 | 0.046 | 0.096 |

| Functional volume parameters | ||||

| Vmp (nm3/nm2) | 0.0232 | 0.0242 | 0.562 | 1.62 |

| Vmc (nm3/nm2) | 0.365 | 0.664 | 13.300 | 25.4 |

| Vvc (nm3/nm2) | 0.463 | 0.875 | 25.400 | 36.6 |

| Vvv (nm3/nm2) | 0.0334 | 0.096 | 0.754 | 2.75 |

| Sample | Position on the Sample | Nanomechanical Characteristics | ||

|---|---|---|---|---|

| Adhesion Force (nN) | Deformation (nm) | Young’s Modulus (MPa) | ||

| AzoPI | All over the surface | 12.6 ± 0.8 | 5.1 ± 0.2 | 294.8 ± 20.5 |

| AzoPI 45/10 | SRG top hills | 11.6 ± 0.3 | 6.3 ± 0.1 | 299.8 ± 5.5 |

| SRG middle slopes | 6.2 ± 0.7 | 8.9 ± 0.1 | 195.1 ± 4.6 | |

| SRG bottom valleys | 12.1 ± 0.1 | 6.7 ± 0.1 | 311.0 ± 5.2 | |

| SRG base line | 11.4 ± 0.4 | 6.8 ± 0.2 | 302.8 ± 9.1 | |

| AzoPI 45/100 | SRG top hills | 12.9 ± 1.9 | 5.4 ± 0.2 | 294.2 ± 9.0 |

| SRG middle slopes | 3.2 ± 0.4 | 8.9 ± 0.3 | 128.9 ± 8.6 | |

| SRG bottom valleys | 13.3 ± 0.1 | 5.1 ± 0.2 | 307.9 ± 12.2 | |

| SRG base line | 12.4 ± 0.3 | 5.1 ± 0.1 | 301.9 ± 12.3 | |

| AzoPI Sample | Parameter | |||||

|---|---|---|---|---|---|---|

| ρp (g/cm3) | Vo (Å3) | Vf (Å3) | FFV | ree (Å) | CED × 107 (cal/m3) | |

| Stage I | 1.20 | 25,012 | 17,105 | 40.61 | 31.06 | 5.8409 |

| Stage II | 1.19 | 25,025 | 17,642 | 41.35 | 36.55 | 5.7983 |

| Stage III | 1.21 | 24,993 | 16,649 | 39.98 | 28.95 | 6.0190 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stoica, I.; Epure, E.-L.; Constantin, C.-P.; Damaceanu, M.-D.; Ursu, E.-L.; Mihaila, I.; Sava, I. Evaluation of Local Mechanical and Chemical Properties via AFM as a Tool for Understanding the Formation Mechanism of Pulsed UV Laser-Nanoinduced Patterns on Azo-Naphthalene-Based Polyimide Films. Nanomaterials 2021, 11, 812. https://0-doi-org.brum.beds.ac.uk/10.3390/nano11030812

Stoica I, Epure E-L, Constantin C-P, Damaceanu M-D, Ursu E-L, Mihaila I, Sava I. Evaluation of Local Mechanical and Chemical Properties via AFM as a Tool for Understanding the Formation Mechanism of Pulsed UV Laser-Nanoinduced Patterns on Azo-Naphthalene-Based Polyimide Films. Nanomaterials. 2021; 11(3):812. https://0-doi-org.brum.beds.ac.uk/10.3390/nano11030812

Chicago/Turabian StyleStoica, Iuliana, Elena-Luiza Epure, Catalin-Paul Constantin, Mariana-Dana Damaceanu, Elena-Laura Ursu, Ilarion Mihaila, and Ion Sava. 2021. "Evaluation of Local Mechanical and Chemical Properties via AFM as a Tool for Understanding the Formation Mechanism of Pulsed UV Laser-Nanoinduced Patterns on Azo-Naphthalene-Based Polyimide Films" Nanomaterials 11, no. 3: 812. https://0-doi-org.brum.beds.ac.uk/10.3390/nano11030812